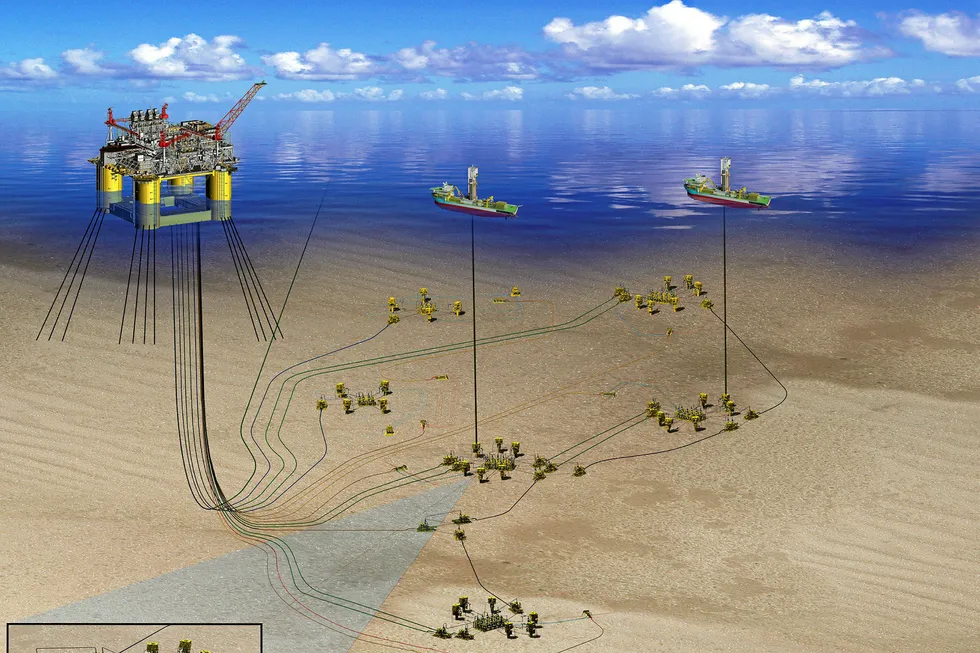

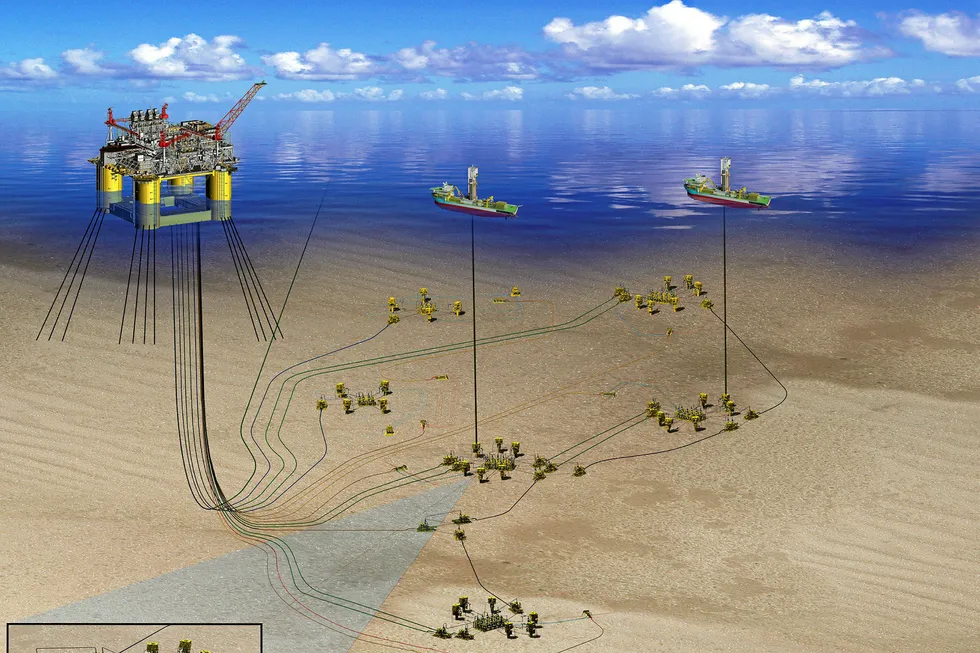

Facing up to the HTHP challenge

Extreme reservoir pressures and temperatures are straining the limits of current deep-water technology — and putting pressure of a different sort on US regulators charged with approving field development plans

Extreme reservoir pressures and temperatures are straining the limits of current deep-water technology — and putting pressure of a different sort on US regulators charged with approving field development plans