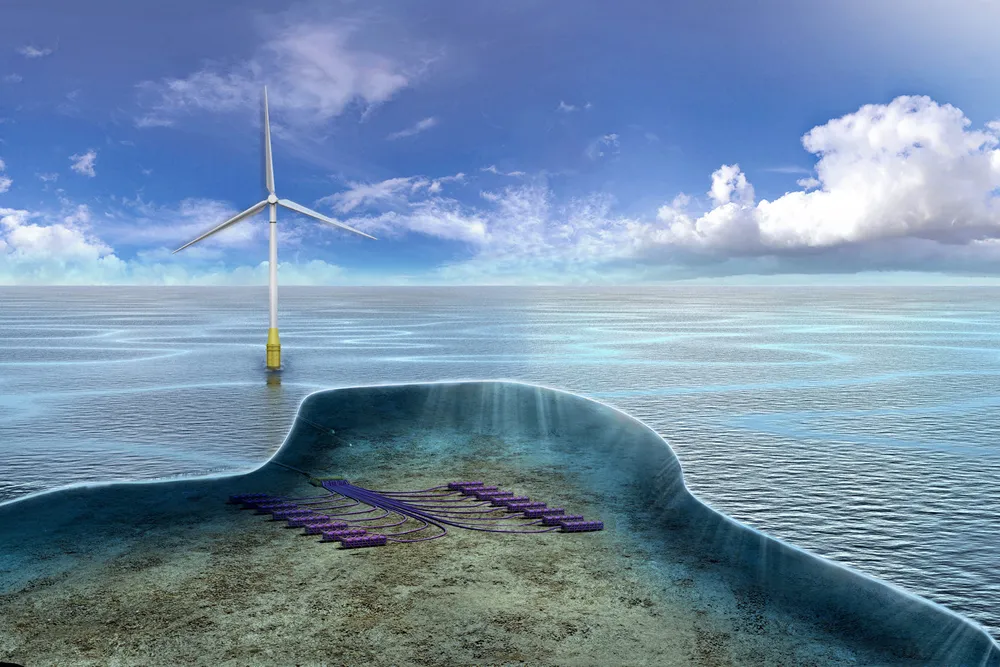

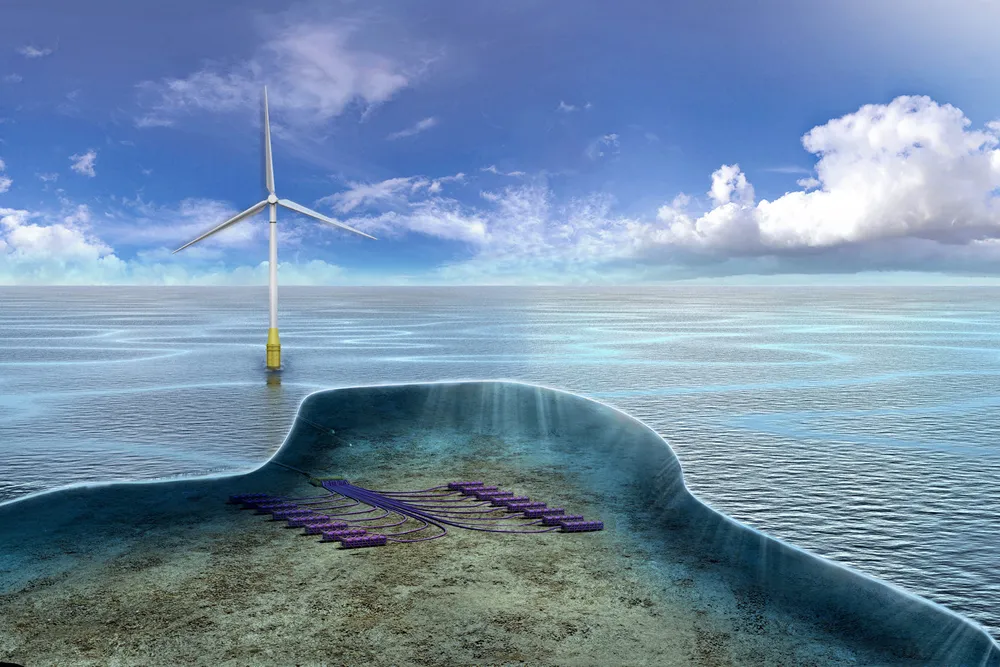

Existing oil and gas infrastructure has potential in offshore green hydrogen

Pilot projects are exploring how to mix hydrogen in natural gas pipelines and use oil and gas platforms for electrolysis.

Pilot projects are exploring how to mix hydrogen in natural gas pipelines and use oil and gas platforms for electrolysis.