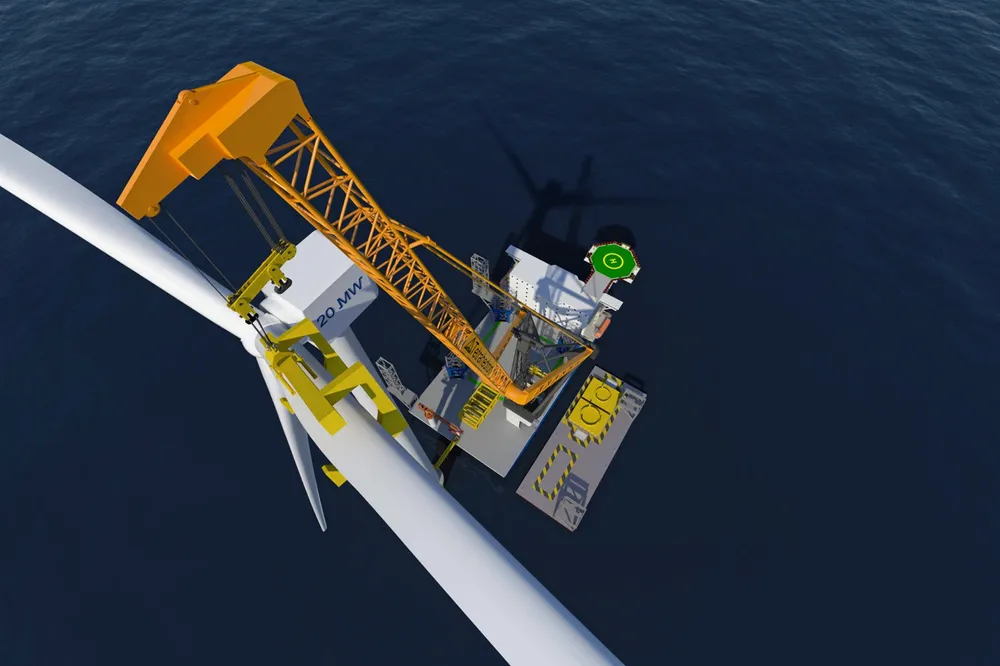

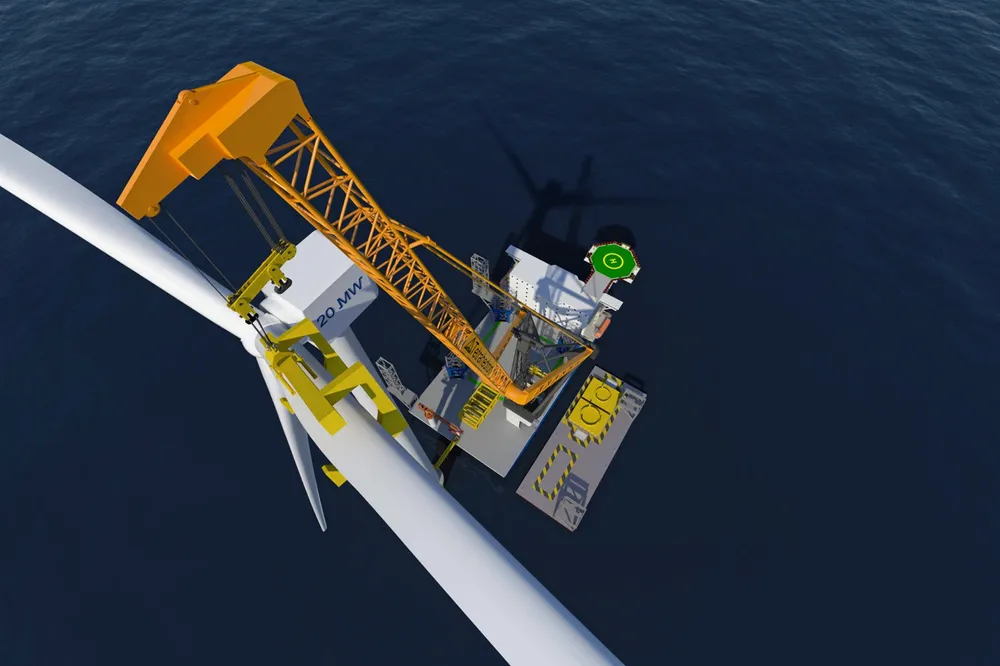

Jacked-up: US rig design veteran launches 'cost-halving' US wind installation feeder

Friede & Goldman ties up with Tetrahedron on concept combining smaller-model jack-ups with a next-generation crane and ocean barges for emerging

Friede & Goldman ties up with Tetrahedron on concept combining smaller-model jack-ups with a next-generation crane and ocean barges for emerging